Part Two: Designing Products for Rotational Molding

Kiss-Off Ribbing, Single Point Kiss-Offs and Kiss-Throughs

Part Two: Designing Products for Rotational Molding

Kiss-Off Ribbing, Single Point Kiss-Offs and Kiss-ThroughsKiss-Off Ribbing, Single Point Kiss-Offs and Kiss-Throughs

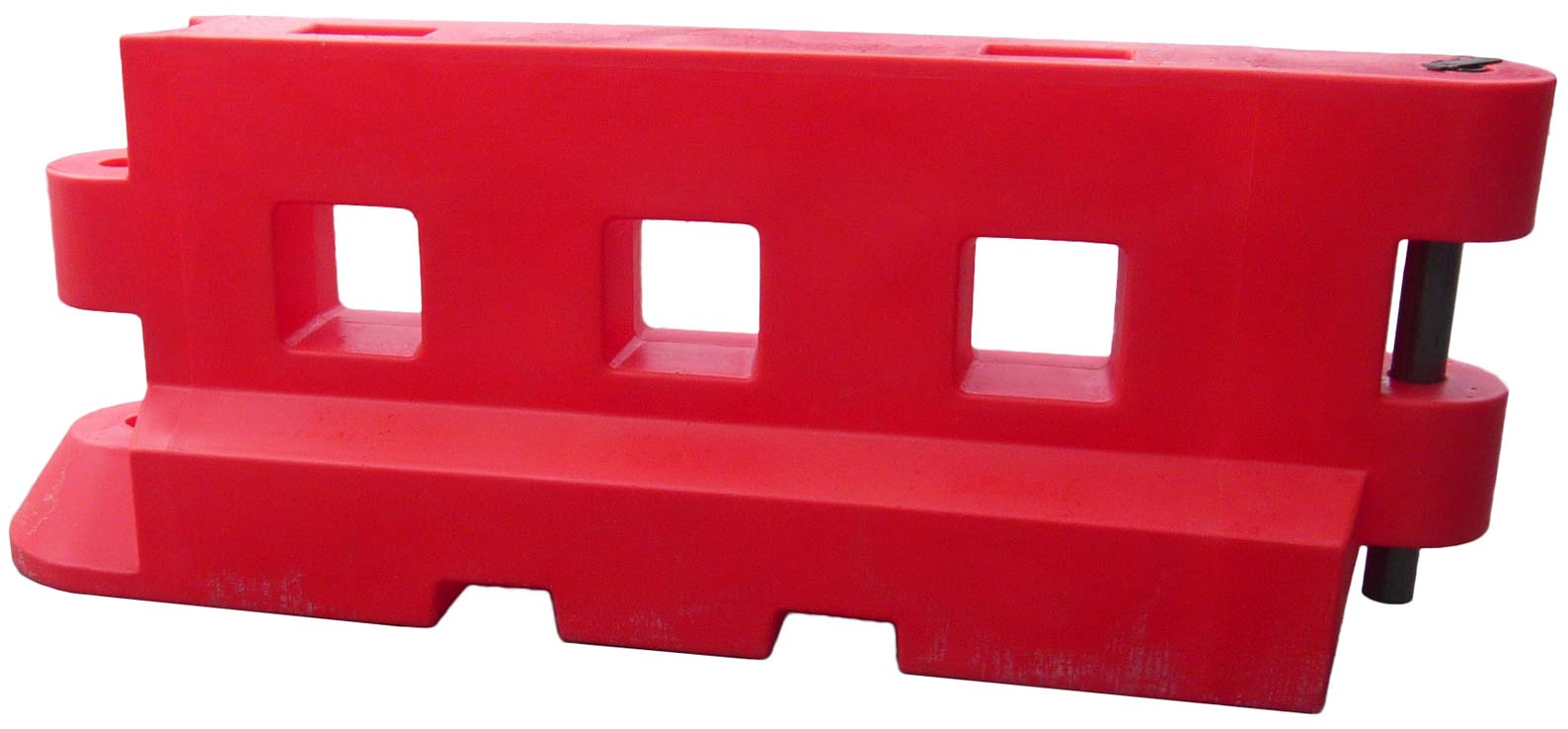

The provision of kiss-off features is a capability that is unique to rotomolded parts. With this form of reinforcement, two closely spaced linear wall sections can be effectively tied together (Fig 23). This will significantly enhance structural stiffness, strength and dimensional stability. Kiss-off features are used to counteract warpage in large, flat surfaces and to provide added strength and baffling inside fluid tanks.

Kiss-off features may take the form of ribs (where there is a tie over a length of the part), single point-point kiss-offs (a tie in one location only) or kiss-throughs (effectively a molded passage through the part from side to side).

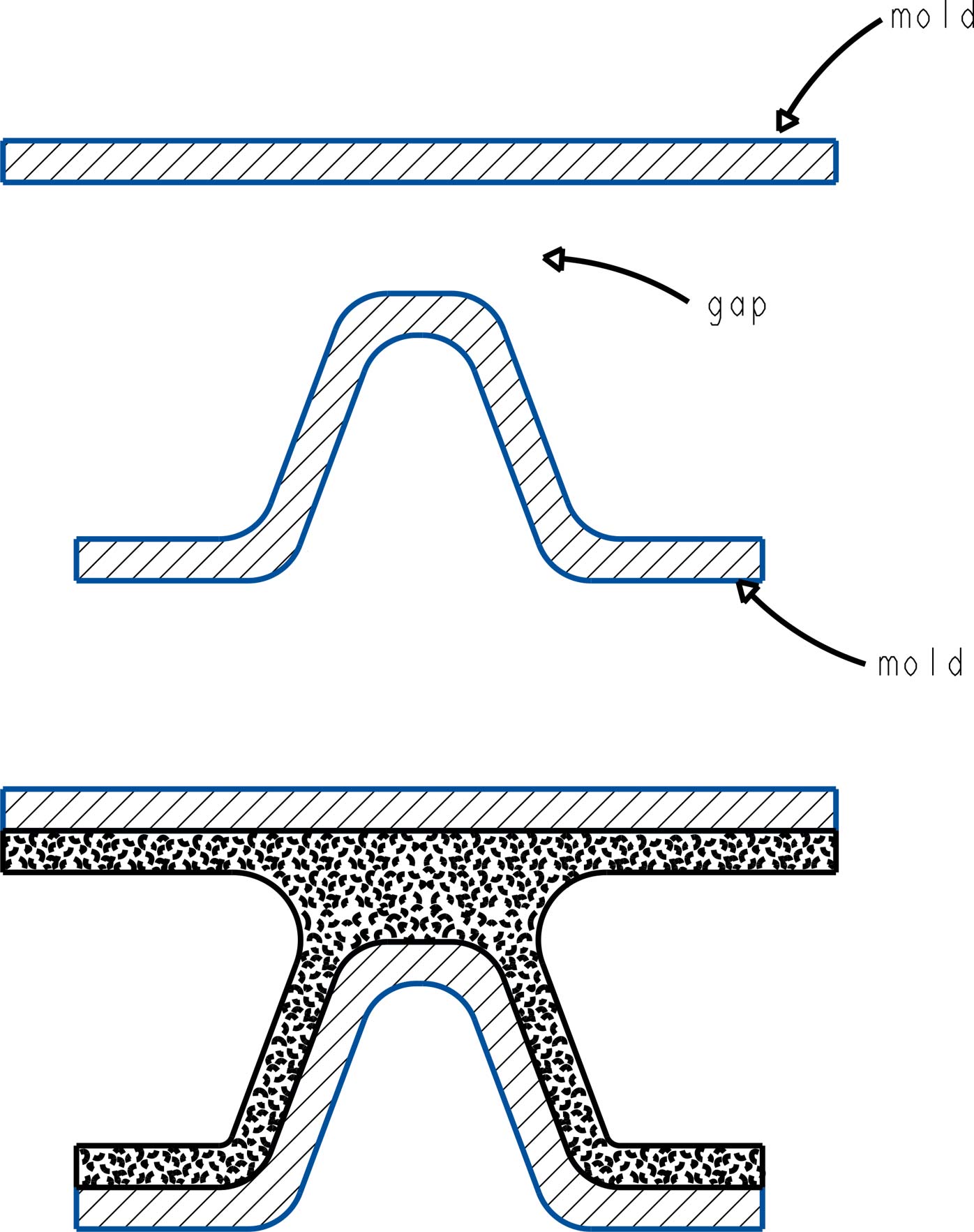

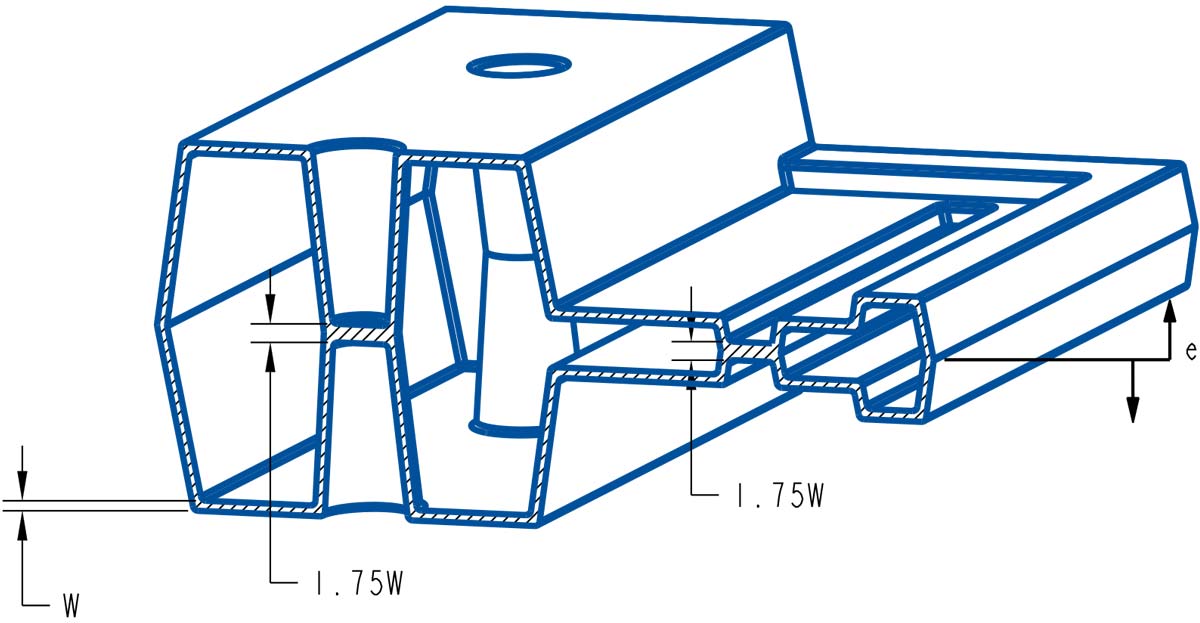

To produce a kiss-off, as a rib or single point, there must be a gap between the kiss-off protrusions on each side of the mold. The size of this gap, relative to the nominal wall thickness, is critical. Too large a dimension will mean that a satisfactory tie cannot be established. Too small a dimension will act as a barrier to powder flowing into the gap and being able to form the tie. In practice, gap dimensions are often established by trial-and-error, or by prior experience. A gap between the two kiss-off points of 175% of the nominal wall thickness is a good starting point (Fig 24). These proportions will provide an adequate weld line, while leaving sufficient space for the powder to move into the gap to form the tie. One common strategy is to make a smaller gap during mold manufacture and then grind off material subsequently in stages, until a satisfactory weld depth has been established.

When working with two mold walls that are located some distance apart, but are intended to kiss-off, the kiss-off protrusions will be relatively deep. This may result in inadequate heat getting down to the tip of the protrusion; less heat will result in less material being laid down in this critical area. The use of air amplifiers (Fig 25) or heat pins will increase heat concentration and these devices are controllable in terms of the location of the heat. An alternative strategy could be to reduce the thickness of the mold metal in the kiss-off area, although this may prove difficult to effectuate in some cases. The use of so-called “surface enhancers” (polyethylene wax formulations that can be sprayed on to the protrusions) may assist local material lay-up, as may localized texturing.

Kiss-Throughs (Fig 26) are often used to facilitate part features such as: axle-pins for wheels, hinge-pin cores, drain plugs or a leak-proof cores. The design of the passage through the mold should try to maximize the likely flow of hot air; once again, air amplifiers may be required to ensure sufficient material build-up.