Part Two: Designing Products for Rotational Molding

Reinforcing Ribs

Part Two: Designing Products for Rotational Molding

Reinforcing RibsReinforcing Ribs

Ribs are an important design detail on rotationally molded plastic parts. Rotomolded parts have walls which can be thin in comparison to the overall size of the part. The strategic placement of ribs can increase the part’s stiffness while maintaining a minimum nominal wall thickness. The correct use of stiffening ribs can result in strong, lightweight parts that can be produced on relatively short molding cycles and therefore at optimum cost.

Stiffening ribs can be designed in a range of configurations, in terms of width, depth and spacing. Deep, narrow ribs (Fig 20) can be viewed as a series of closely spaced parallel walls, so the design guidelines for parallel walls should be followed.

As a general rule, several shallow ribs will be easier to produce than a single deep rib.

Solid ribs, similar to those routinely used in injection or compression molded parts, will present significant challenges in rotationally molding. Their use is not recommended, unless there are pressing reasons for using them and some significant design development (including possible tool modifications) will be involved in successful implementation.

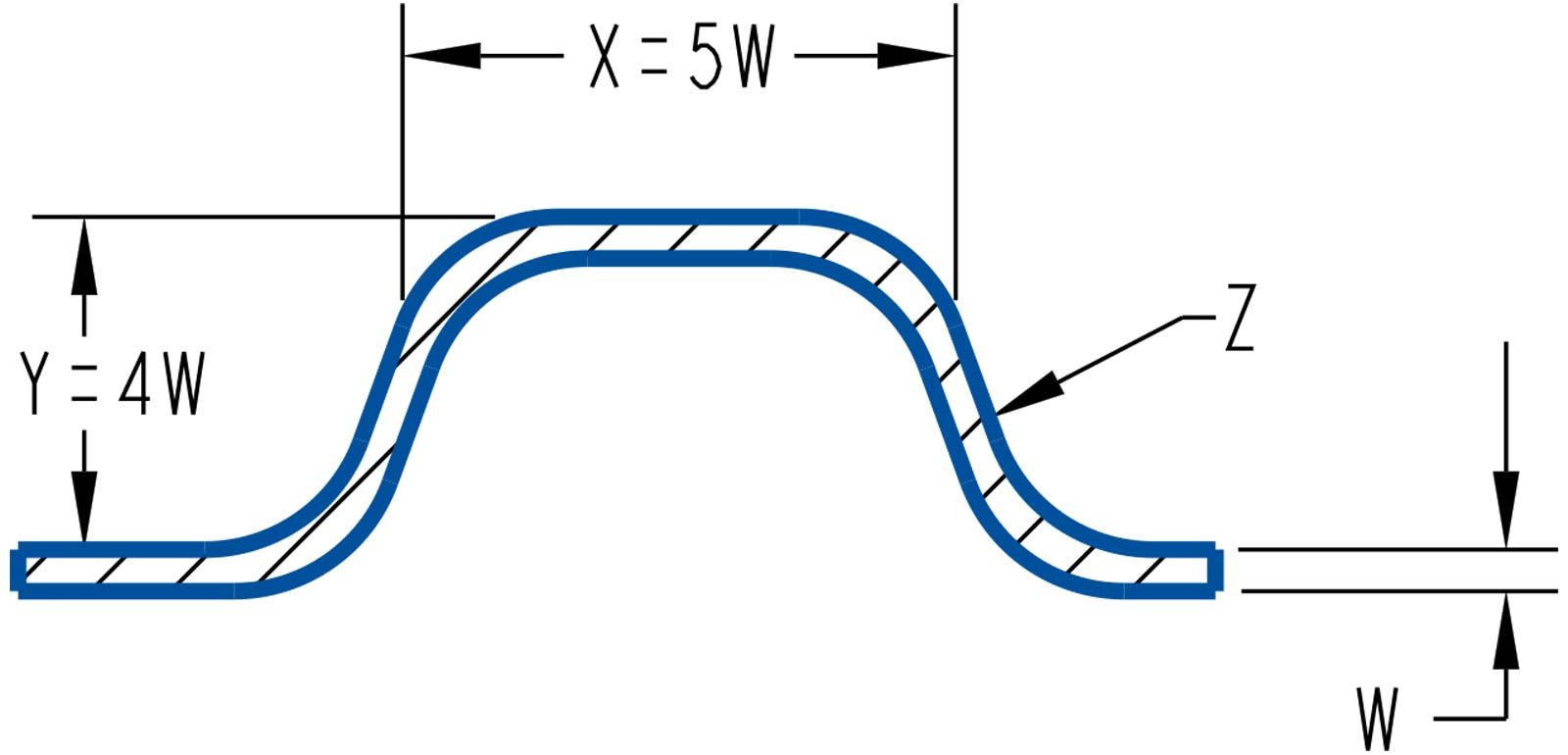

A good average proportion for rotationally molded stiffening ribs would be a width of at least five times the nominal wall thickness and a height of at least four times the nominal wall thickness (Fig 21). As the height of the rib is increased, so will be the stiffness of the structure; this is main factor. A wider rib will increase the probability of proper formation. For best results, the width of the rib should be greater than its height.

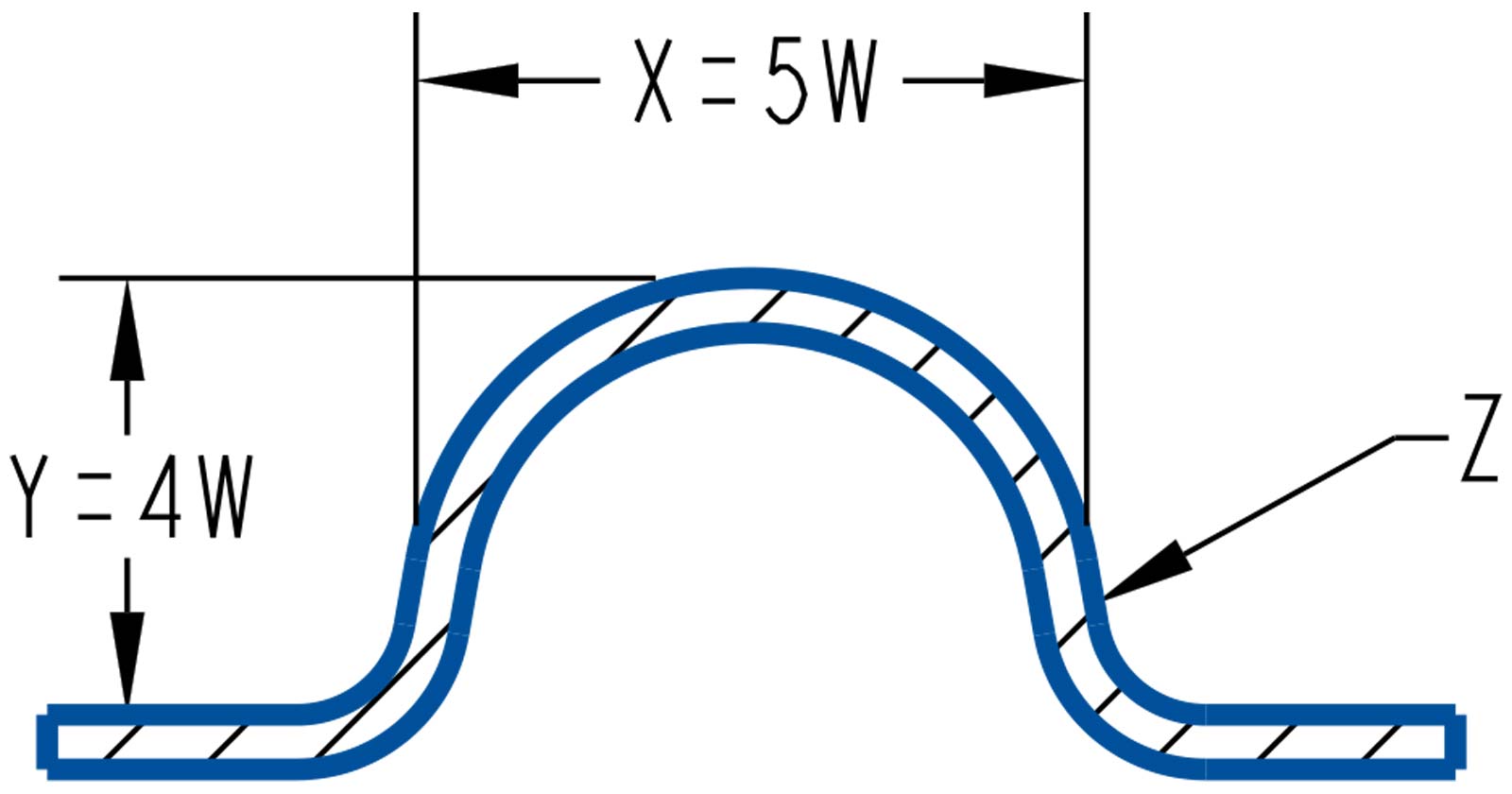

Ribs with a more rounded profile (Fig 22) will generally be the easiest to produce. However, for the same shot weight of material used, a rectangular-shaped reinforcing rib is likely to provide more stiffness.

The side walls of stiffening ribs should be provided with an adequate taper, to improve their release from the mould walls. Suitable taper angles are shown in the Section “Draft Angles”.