Part Two: Designing Products for Rotational Molding

Corner Angle Limits

Part Two: Designing Products for Rotational Molding

Corner Angle LimitsCorner Angle Limits

Full formation at the corners of a three-dimensional part should be carefully considered at the design stage. Very tightly angled corners are likely to present bridging problems similar to those associated with narrow spaced walls. Corner angles that are less than those recommended may result in parts which are not completely filled out.

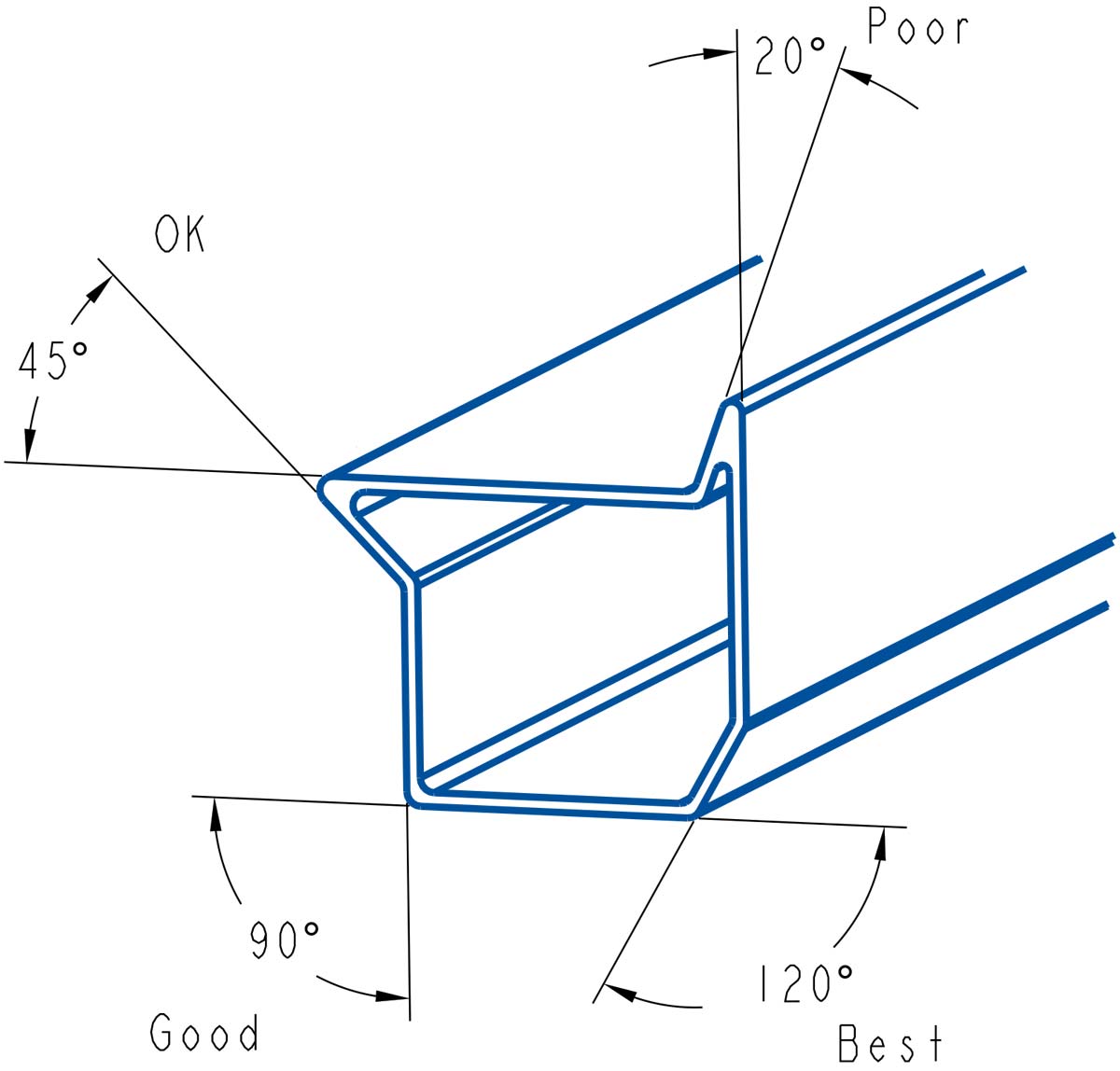

Fig 19 shows recommended limits for corner angles in rotomolding.

The reasons for such problems are similar in nature to narrow spaces. A standard powder will have difficulties in flowing into tight corners and bridging problems and associated defects are likely. In addition, it is possible for an air pocket to become trapped at the point of a corner and prevent full powder flow. When the part is fully molded, there may be missing material at this point. This is likely to result in a reject part and added part cost.

Irregularly shaped parts with corner angles of 90° or greater can be molded with relative ease in any plastic material suitable for the end-use requirements of a part.

Corner angles of less than 90° may require greater care and attention by the molder. Powder quality will start to become more critical as corners become more acute. Corner angles of 45° should be able to be consistently achieved with standard polyethylene powders and the minimum recommended angle for such materials is 30°.

Polymers delivered to the mold in liquid form (eg PVC plastisol) should flow well enough to meet the same limits as stated above.

Whilst it will always be better to “design out” problems, sharper corners may occasionally be unavoidable. In such cases, there are some molding expedients that can be tried.

Use of a powder with better Dry Flow may help to avoid corner filling problems. Generally, this will imply a coarser powder than standard. Micropellets, which are very small pellets with an average particle size that is approximately 50% larger than standard powder, have been known to eliminate problems in some cases. Issues associated with trapped air at the bottom of the corner can be addressed by provide a small (1/16 inch) hole in the mold, at the tip of the corner. This allows air to pass out during cooking and a small sprue will be formed in the part, which can be trimmed off, after de-molding.

It would be wise to reserve such expedients as being for use only when the requirements of the part make very sharp corners completely unavoidable.

A limiting factor on corner angles is that there must be an adequate radius at their tip, ie the point where the two walls meet. The design guidelines given for “minimum wall separations” and “corner radiuses” also apply to corner angles.