Part Two: Designing Products for Rotational Molding

Undercuts

Part Two: Designing Products for Rotational Molding

UndercutsWelcome to the new ARM website!

Over the next week, we’ll be making updates, filling in missing items, and continuing to improve your experience.

We’re confident this new site will be a major upgrade: easier to use, more intuitive, and designed to provide greater value for our member companies and their employees.

Please note: the ARM Training Academy (our online certificate program) will be paused for approximately three weeks while we transfer your data and sign-on credentials.

If you need immediate assistance, please contact the ARM staff. We’re here to help.

Part Two: Designing Products for Rotational Molding

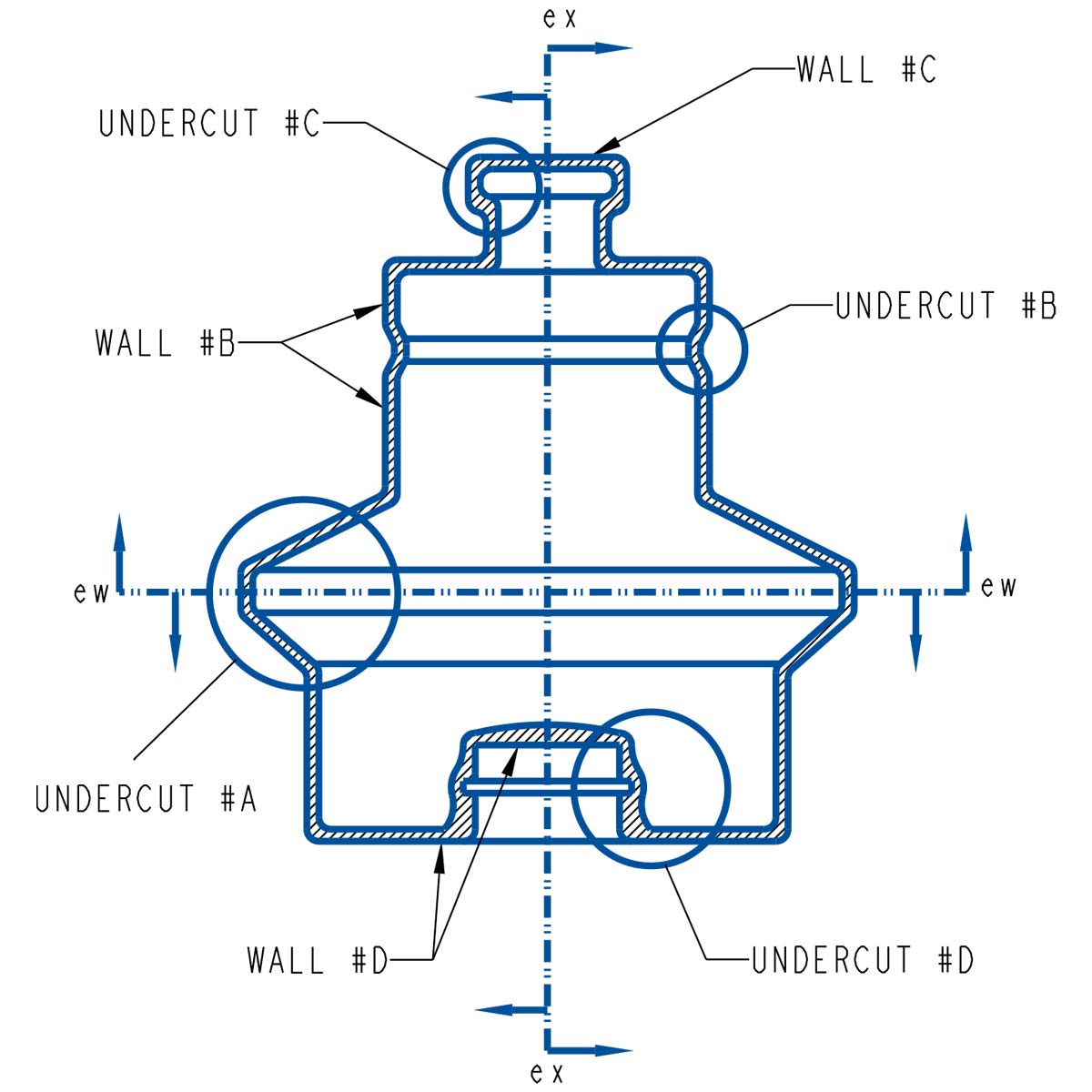

UndercutsIn rotomolding, the term “undercut” refers to any inwardly or outwardly projecting section that is parallel to the parting line of the mold. Such a feature of any size will require the part to be deformed in order to release it from the mold. In this respect, the shrinkage of polyethylene is helpful, as is the material’s relative flexibility at typical demolding temperatures.

It is difficult to be precise about the design of undercuts for rotomolded parts, because circumstances vary so much. Each different type of undercut will require a different set of considerations (Fig 33):

In many cases, ease of demolding will be improved by the use of higher slip mold release agent on the affected section of the mold.

Whilst a simple two-piece mold will usually be the lowest cost option, provision of removable sections can solve many undercut issues.

If you are already a member, please set up and log in to your member account by clicking "Create an Account" below. This option is also for current individual members and staff of company members who need to login, but do not have a user account set up.

Once logged in, you can:

Train your team, reduce scrap, and connect with the rotomolding community.

ARM delivers training that works through the ARM Training Academy, including courses in Operator Training, Health & Safety, Wall Thickness Control, and more.

You’ll gain practical insight from peers and experts through webinars, troubleshooting calls, and classic videos focused on process improvement.