Part One: The Rotational Molding Industry

Rotational Molding Machines

Part One: The Rotational Molding Industry

Rotational Molding MachinesRotational Molding Machines

There are a number of different basic designs and layouts for rotational molding machines.

Biaxial machines share many common features, but a variety of layouts are available.

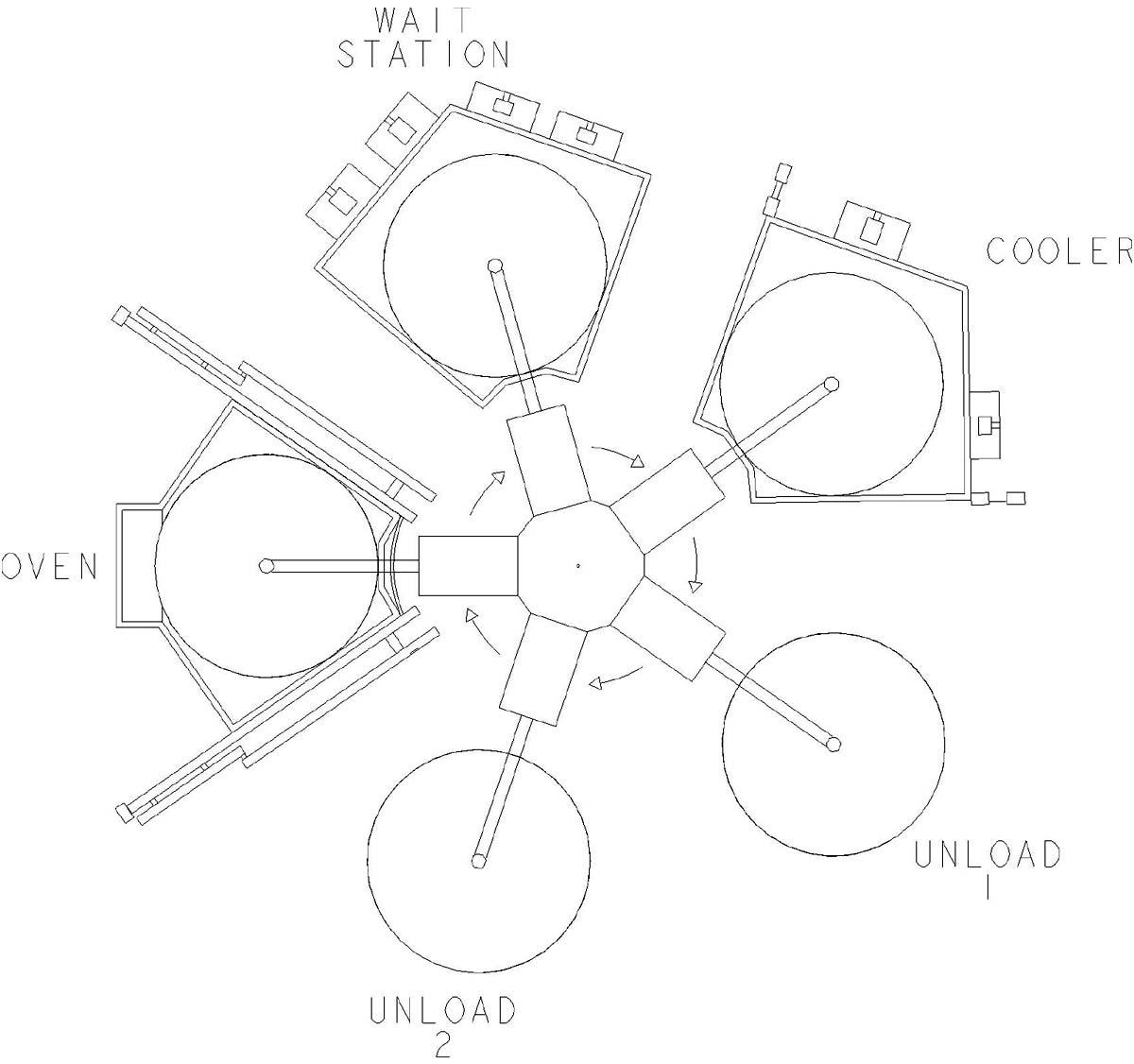

Carousel style machines (Fig 5) feature discrete locations for the oven, cooler and servicing station. Additional locations may be available: a “wait station” between oven and cooler and multiple servicing stations. Moulds are mounted on arms which move from location to location around a central spindle. The number of separate arms provided will depend on process constraints related to the types of products being manufactured.

Turret carousel machines operate on a fixed relationship between arms; when one arm moves out of the oven into the cooler, another arm moves from cooler to service and a third arm moves from service into the oven. Turret machines offer excellent productivity, provided that cook, cool and service times are all the same. In practice, this means that they are suitable for making similarly sized products on each arm.

Independent arm carousel machines feature arms with no fixed relationship between each other; as the name implies, arms can move independently from each other. This provides enhanced flexibility of operation, but this can be at the cost of productivity.

Another common layout is a shuttle machine (Fig 6). Typically these have two arms, which move in a common linear movement, but in opposite directions. There is a shared oven in the middle of the machine and each end of the machine has a combined cooling and servicing station. While one arm is in the oven, the other is cooling and being serviced. Shuttle machines have a more compact layout compared to carousel machines and, size-for-size, tend to have a lower capital cost. However, their productivity is usually inferior to carousel types.

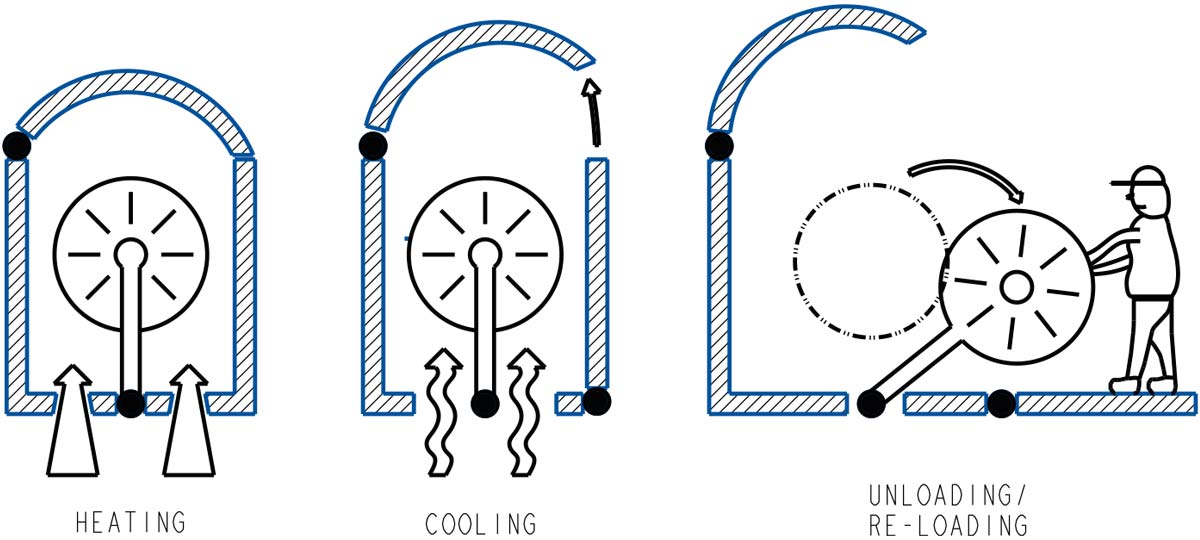

In a clamshell machine (Fig 7), all operations are carried out within the same envelope. There is only one arm, which goes through its cook cycle in an oven which is subsequently used as a cooler, once the burner is shut off. At the end of the cooling cycle, the arm articulates out of the front of the machine for servicing. Clamshell machines offer maximum process flexibility (cook, cool and service cycles can all be different from each other), but productivity is low compared to other types.

In rock and roll motion machines, the oven is usually part of the rocking mechanism, although some machines offer a rocking arm within a large, fixed oven. These tend to be specialist machines.

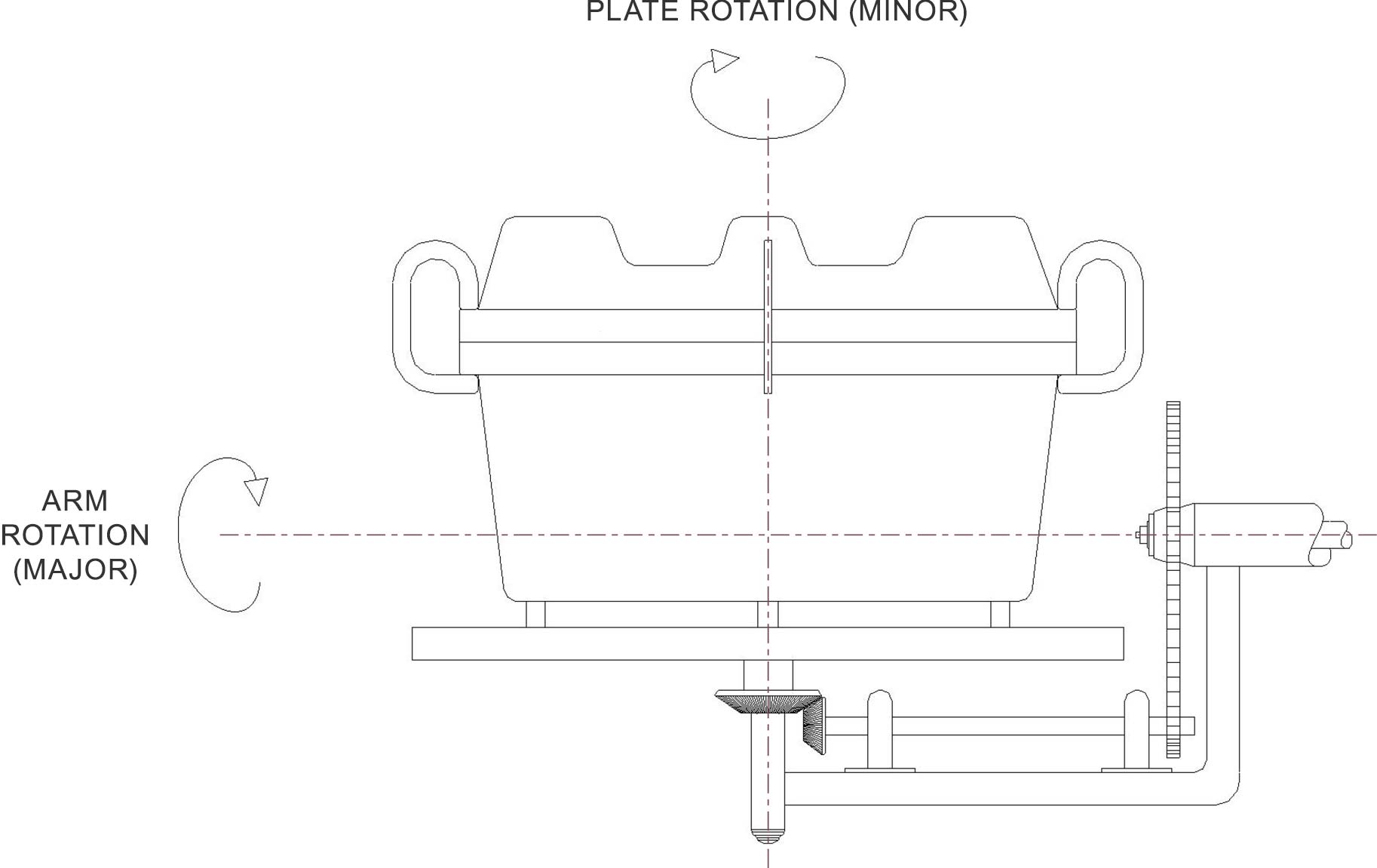

Arm rotation, which is slow speed, is usually achieved by independent motors driven through a combination of gears, chains and sprockets. Some machines are fitted with encoders, so that rotations can be accurately controlled and changed mid-cycle.

Biaxial motion is most commonly achieved using a straight arm which is a hollow tube with another driving shaft inside it; the arm components can be driven at separate rotation speeds by individual motors. A gear arrangement at the end of the arm converts the inner shaft rotation into a motion at 90°, which drives a circular plate on each side. In this arrangement (a “straight” arm), there can be molds mounted on either side of the arm. In order to accommodate very large molds, the arm can be cranked to make a so-called “offset” arm, in which case there is only one plate provided. This arrangement makes maximum use of the oven’s size. See Fig 8.

It is quite usual for carousel machines and shuttle machines to be provided with a mixture of straight arms and offset arms, depending on the size and number of products being made.

On an industrial scale, most ovens are fired by natural gas or propane / LPG, depending on availability of supplies. Oil or diesel burners have also been used, although these tend to be messy. The steep heating ramp required to heat an arm, mold and its contents makes electrical heating impractical, except for small capacity machines.

Over the last decade, serious attempts have been made to make the rotomolding process more completely automated and a few speciality machine designs have been developed. These often rely on direct contact heating, either by hot fluid channels cut into the mold wall or by electrical heating elements embedded in the mold wall. An external oven is not required (Fig 9). Benefits of these machines include reduced labor cost, faster cycle times and increased process flexibility. However, the heating modifications make molds relatively expensive, compared to standard molds.