Part Two: Designing Products for Rotational Molding

Flatness Considerations

Part Two: Designing Products for Rotational Molding

Flatness ConsiderationsWelcome to the new ARM website!

Over the next week, we’ll be making updates, filling in missing items, and continuing to improve your experience.

We’re confident this new site will be a major upgrade: easier to use, more intuitive, and designed to provide greater value for our member companies and their employees.

Please note: the ARM Training Academy (our online certificate program) will be paused for approximately three weeks while we transfer your data and sign-on credentials.

If you need immediate assistance, please contact the ARM staff. We’re here to help.

Part Two: Designing Products for Rotational Molding

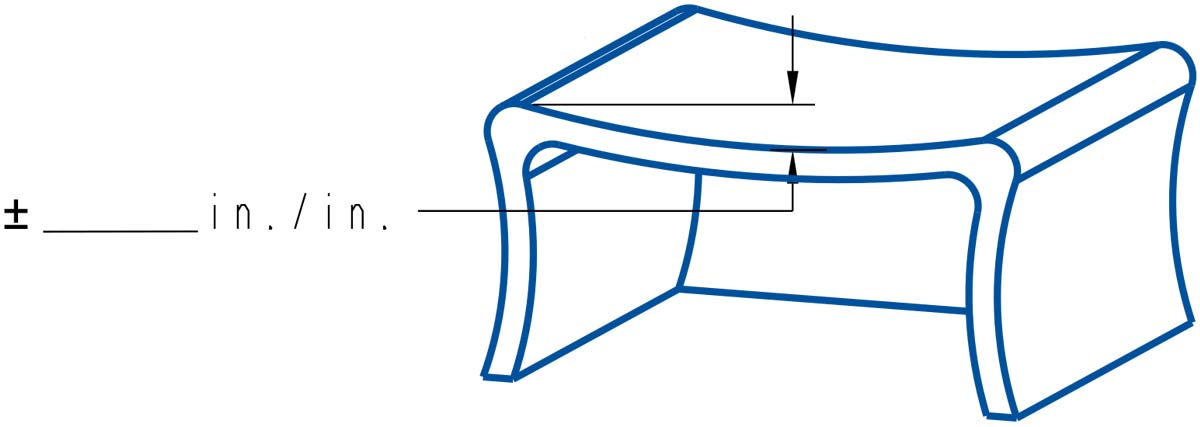

Flatness ConsiderationsRotationally molded parts, like blow-molded parts, are formed in hollow molds, typically without internal structure. This means that the inside surface of the part is, in effect, free-formed. On large flat surfaces, there may be a tendency for the middle of the area to be depressed relative to the outside of the area, creating an internal bowing effect. This tends to become more pronounced as wall thickness increases.

The designer should give consideration to large flat surfaces that have functional or cosmetic attributes. A commercially acceptable flatness tolerance on a polyethylene part would fall in the range of ±0.020 to 0.030 inches per inch (see Fig 15). A precision tolerance of ±.010 inches per inch may be achieved with quality tooling and controlled processing techniques.

Alternative strategies would be to break up flat areas with surface features, or design-in a slight outward contour.

Whilst it is often preferred to avoid large flat surfaces when designing rotationally molded parts, it is possible to incorporate such surfaces if necessary. Experienced molders working with rotationally molded parts containing large flat surfaces can utilize a range of techniques. Flat surfaces may be supported with reinforcing ribs and some designs have successfully incorporated crowns of approximately 0.015 inch-per-inch on flat surfaces. It is also common to use secondary fixtures as a way to ensure that the molded part maintains its shape during post-mold cooling. Some designs incorporate textures, decoration or engraved lettering on flat surfaces, in order to draw attention away from the lack of flatness.

If you are already a member, please set up and log in to your member account by clicking "Create an Account" below. This option is also for current individual members and staff of company members who need to login, but do not have a user account set up.

Once logged in, you can:

Train your team, reduce scrap, and connect with the rotomolding community.

ARM delivers training that works through the ARM Training Academy, including courses in Operator Training, Health & Safety, Wall Thickness Control, and more.

You’ll gain practical insight from peers and experts through webinars, troubleshooting calls, and classic videos focused on process improvement.